What is Manufacturing Technology and How it Improves Efficiency and Quality

Manufacturing technology refers to the tools, machines, systems, and methods used to produce goods in a controlled and repeatable way. It covers physical equipment, digital systems, and production methods that support the creation of parts and finished products. This type of technology supports consistency in output across many production cycles. It allows manufacturers to meet demand with predictable results. Production tasks become more organized through planned processes. Materials move through defined stages from raw input to final form. Workers rely on machines and systems to support daily tasks. Data from production lines guides planning and scheduling. Manufacturing technology supports both small workshops and large facilities. It applies across many industries with different production needs. The goal centers on stable output and reliable processes. Each tool serves a clear role in production flow.

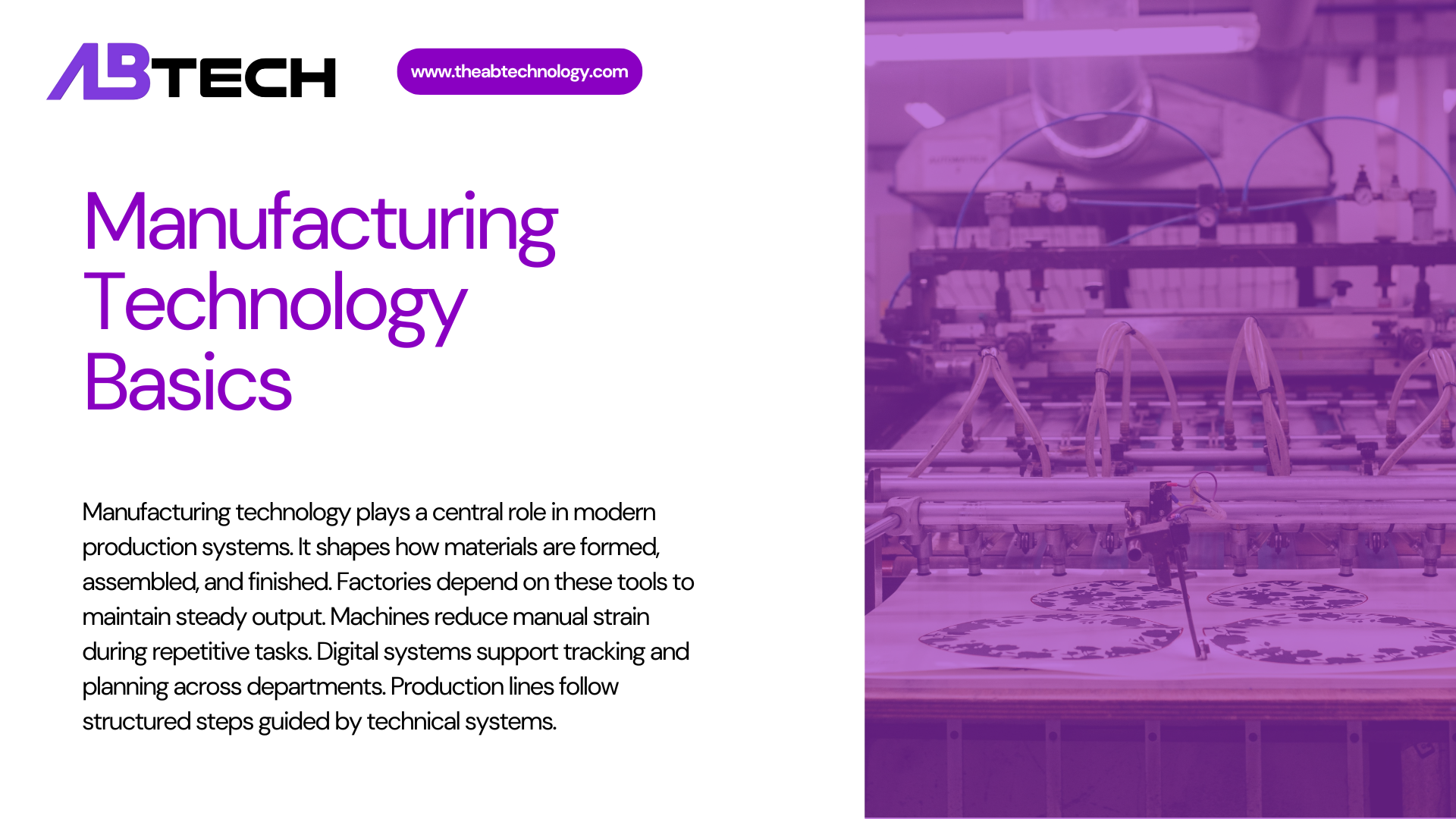

Manufacturing Technology Basics

Manufacturing technology plays a central role in modern production systems. It shapes how materials are formed, assembled, and finished. Factories depend on these tools to maintain steady output. Machines reduce manual strain during repetitive tasks. Digital systems support tracking and planning across departments. Production lines follow structured steps guided by technical systems. These tools allow producers to meet tight schedules. Quality checks occur through built-in measurement tools. Manufacturing technology supports large-scale output with fewer errors. It allows consistent results across long production runs. Businesses rely on it to meet market demand. Production becomes more predictable through structured processes.

Meaning Over Time

The meaning of manufacturing technology has changed as production needs have evolved. Early systems focused on basic mechanical tools. Power-driven machines later increased production speed. Electrical systems introduced better control over equipment. Digital tools expanded monitoring and planning abilities. Computer-based systems added precision to manufacturing tasks. Software tools now guide machine behavior. Production moved from manual control to system-guided processes. Each stage reflected changing industrial needs. Manufacturing technology now includes both hardware and software. Data plays a larger role in production planning. Tools now respond to real-time inputs. The definition expanded alongside industrial growth.

Manufacturing Focused Tools

Technology designed for manufacturing supports production-specific tasks. These tools shape raw materials into usable parts. Machines cut, mold, and assemble components. Control systems guide movements and timing. Sensors track measurements during production. Software supports scheduling and inventory tracking. Equipment responds to programmed instructions. Production tools follow repeatable patterns. Safety systems protect workers during operation. Monitoring tools report performance data. Maintenance systems track machine condition. Each tool serves a clear production purpose.

Manufacturing Technology Types

Manufacturing technology includes many categories used in current production. Each type supports different stages of manufacturing. Some tools focus on shaping materials. Others support assembly and inspection. Digital systems guide coordination across operations. Physical machines handle heavy tasks. Electrical systems manage power and control. Modern production relies on a mix of technologies. Each type addresses specific production needs. Selection depends on product design and scale. These technologies work together within factories. Proper use supports stable production output. Businesses choose systems based on goals. Technology choices shape daily operations.

Automation and Digital Systems

Automation systems manage repetitive manufacturing tasks. Machines perform actions based on programmed steps. Robotics handles precise movements during assembly. Digital manufacturing systems coordinate machine behavior. Sensors provide feedback during operation. Control software adjusts processes as needed. Automated systems reduce manual handling. Production runs remain consistent over time. Monitoring tools detect issues early. Data supports planning and scheduling. Automation supports large-volume production. Systems operate continuously with minimal interruption.

Mechanical and Electrical Tools

Mechanical technologies form the foundation of manufacturing. These tools include presses, cutters, and forming machines. Electrical systems, power, and control equipment. Motors drive machine movement. Control panels allow operator input. Wiring systems distribute power safely. Mechanical parts handle physical force. Electrical systems manage speed and timing. Maintenance keeps equipment running properly. These tools remain common in many factories. They support both simple and complex tasks. Traditional systems remain reliable across industries.

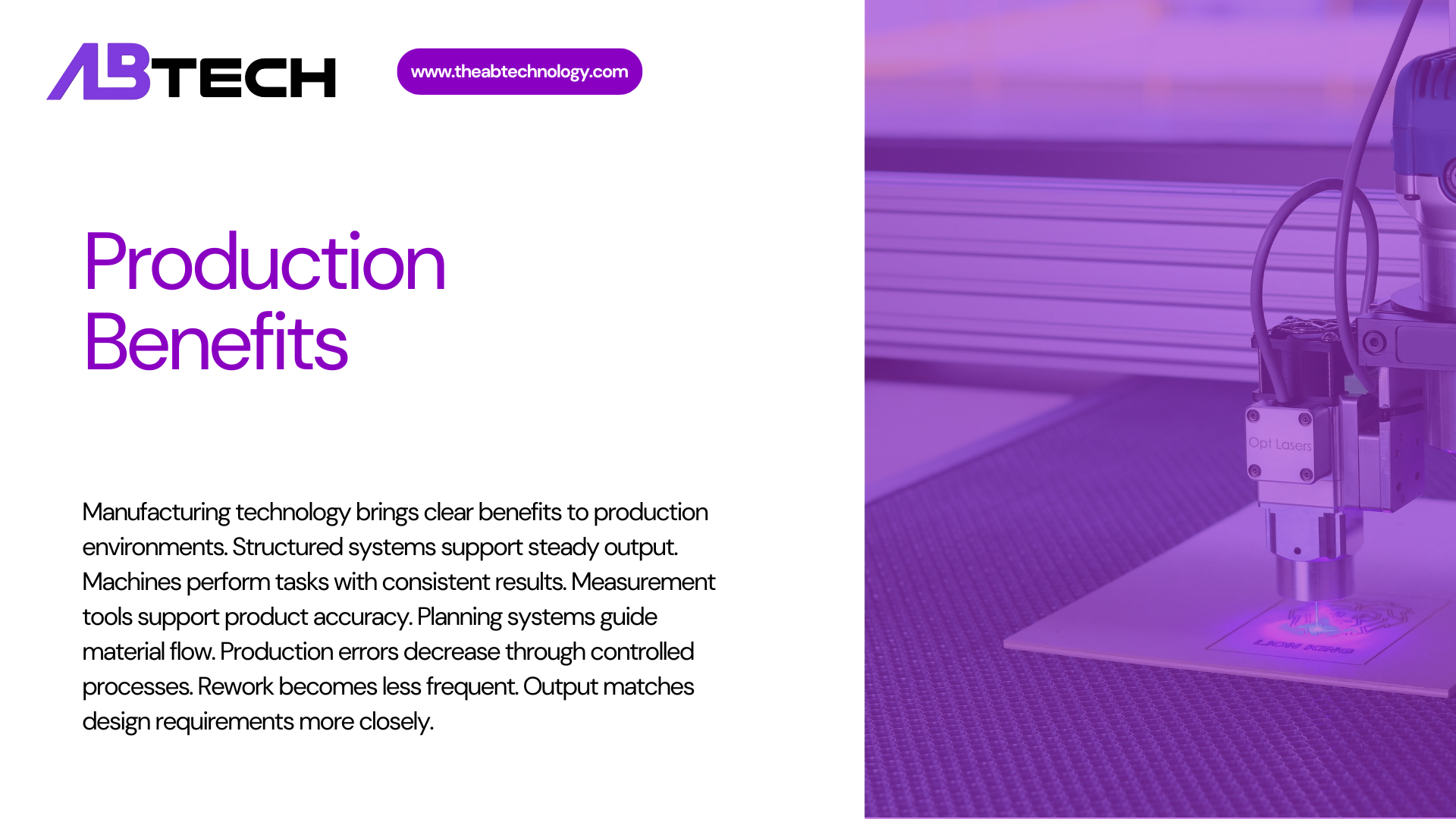

Production Benefits

Manufacturing technology brings clear benefits to production environments. Structured systems support steady output. Machines perform tasks with consistent results. Measurement tools support product accuracy. Planning systems guide material flow. Production errors decrease through controlled processes. Rework becomes less frequent. Output matches design requirements more closely. Production schedules become easier to manage. Technology supports higher production volumes. Workers focus on supervision and control. Products meet defined standards more often.

Output and Quality Gains

Manufacturing technology supports higher production levels. Machines repeat tasks without variation. Products maintain uniform characteristics. Measurement systems detect defects early. Production steps follow defined parameters. Control systems reduce variation. Finished goods match design specifications. Inspection tools verify dimensions and form. Data supports process adjustment. Quality checks occur throughout production. Errors are identified before completion. Output remains consistent across batches.

Safety and Cost Control

Technology supports safer working environments. Machines handle heavy or hazardous tasks. Safety guards protect operators. Sensors stop the equipment during faults. Automated handling reduces manual lifting. Controlled processes limit exposure to risks. Fewer accidents occur with proper systems. Maintenance systems prevent breakdowns. Downtime decreases through planned servicing. Material waste drops through precise control. Costs remain predictable over time. Production stability supports planning.

Manufacturing Technology Challenges

Manufacturing technology presents several challenges for businesses. New systems require worker training. Job roles change as automation increases. Technical skills become more important. Equipment setup requires careful planning. Maintenance demands skilled personnel. System failures can stop production. Technology dependence increases operational risk. Initial investment costs remain high. Updates require ongoing support. Integration across systems takes time. Businesses must manage change carefully. Planning helps reduce disruption.

Workforce Skill Shifts

Workforce roles shift with advanced manufacturing systems. Manual tasks decline in some areas. Technical oversight roles increase. Workers need new skills. Training programs become necessary. Learning curves affect productivity. Some roles may become less common. New positions appear around system support. Experience with digital tools gains value. Communication between teams becomes important. Skill gaps require long-term planning. Workforce adaptation takes time.

Environmental and System Risks

Manufacturing technology can affect environmental outcomes. Energy use rises with advanced systems. Waste management requires planning. Equipment disposal presents challenges. System failures can halt production. Dependence on power increases vulnerability. Data systems require protection. Maintenance errors can cause downtime. Environmental rules affect technology use. Monitoring systems help track impact. Planning reduces negative outcomes. Responsible use supports sustainability.

Real World Applications

Manufacturing technology appears across many industries. Each sector applies tools differently. Production needs shape system design. Technology supports complex product requirements. Processes vary by material type. Scale influences equipment choice. Factories adapt systems to specific goals. Production methods reflect industry standards. Technology supports precision and repeatability. Planning tools guide scheduling. Real-world use shows broad adaptability. Manufacturing technology fits diverse applications.

Industry Use Examples

Automotive production uses structured assembly systems. Aerospace manufacturing relies on precision tools. Electronics production requires fine measurement systems. Each sector uses specialized equipment. Production steps follow strict guidelines. Quality checks occur at many stages. Materials require careful handling. Digital systems support traceability. Production lines adjust to product design. Safety systems protect workers. Industry standards guide technology use. Output meets strict requirements.

Business Process Innovation

Businesses adapt manufacturing technology to improve processes. Production layouts change over time. Systems support new product designs. Data informs planning decisions. Scheduling tools balance workloads. Equipment upgrades support growth. Process changes follow performance data. Manufacturing technology supports experimentation. Small adjustments improve outcomes. Businesses respond to market needs. Technology supports gradual improvement. Process refinement remains ongoing.